The fully automatic 6kW large-format fiber laser tube and sheet cutting machine offers an exceptionally large working area, with dimensions up to 26,000mm x 3,500mm, making it ideal for processing oversized metal sheets and tubes. The machine boasts cutting precision of ±0.03mm, ensuring high-accuracy results even on the largest workpieces.

The fully automatic 6kW large-format fiber laser tube and sheet cutting machine offers an exceptionally large working area, with dimensions up to 26,000mm x 3,500mm, making it ideal for processing oversized metal sheets and tubes. The machine boasts cutting precision of ±0.03mm, ensuring high-accuracy results even on the largest workpieces.

It is compatible with a wide range of materials, including stainless steel, carbon steel, galvanized steel, aluminum, copper, brass, and various metal alloys. Key functional highlights include:

-

Intelligent real-time monitoring

-

Efficient rapid-cooling system

-

Eco-friendly fume extraction and filtration

The machine is CE-certified, fully meeting EU safety and performance standards, which enables smooth market access across Europe and other regulated markets.

Supplier Advantages

The supplier primarily exports to Slovenia, Austria, and the United States, and specializes in fully customized solutions as well as design-based manufacturing services. All machines come with relevant product certifications and have been widely adopted by clients in diverse industrial sectors.

Introducing the BH Series – Rail-Mounted Ultra-Large Format Fiber Laser Metal Cutting Machine

A revolutionary solution designed to replace traditional cutting methods for extra-large metal sheets and tubes. The BH Series is engineered to tackle oversized metalwork with unmatched speed, accuracy, and intelligence.

Breakthrough Design for Massive Cutting Needs

This next-generation machine features a super-sized working bed that supports metal sheets up to 26,000mm in length and 3,500mm in width. Whether you’re handling ultra-thick carbon steel or long aluminum profiles, the BH Series is built to deliver.

The rail-mounted structure enhances machine stability and supports high-speed, high-precision movement across the entire cutting area. This architecture ensures rigid motion control and reduces vibration during cutting, even on the largest surfaces.

Precision Meets Efficiency

-

Laser Power: 6kW

-

Cutting Accuracy: ±0.03mm

-

Application Scope: Ideal for cutting thick, heavy, and oversized metal plates

-

Material Compatibility: Carbon steel, stainless steel, galvanized steel, iron, aluminum, copper, gold, silver alloys, and more

-

Smart Cutting Software: Real-time monitoring, automated nesting, edge tracking, and fault detection

Ideal For Industries Such As:

-

Heavy machinery manufacturing

-

Shipbuilding and aerospace

-

Bridge and steel structure construction

-

Wind power and new energy sectors

-

Large-scale metal fabrication workshops

Enhanced Operational Features:

-

User-Friendly Interface: Touchscreen operation with multi-language support and intuitive controls

-

Advanced Safety Mechanisms: Includes protective covers, automatic fire detection, and emergency stop features

-

Smart Connectivity: Remote diagnostics, performance tracking, and real-time data reporting for production management

-

Green Manufacturing: Built-in fume extraction system and optimized energy consumption for eco-friendly operation

Certificate

Application Fields

This machine is ideal for industries such as:

-

Heavy steel structure manufacturing

-

Shipbuilding and marine engineering

-

Oil and gas pipeline fabrication

-

Construction and architecture

-

Industrial machinery and vehicle frames

Comprehensive Fiber Laser Tube Cutting Solution

Covering a full spectrum of laser power from 1.5kW to 12kW, this machine handles tube lengths up to 7,500mm with high accuracy and efficiency. It is engineered for the versatile processing of round, oval, racetrack-shaped, angle steel, channel steel, I-beams, and other irregular profiles. With its intelligent automation features, it significantly reduces manual labor and maximizes productivity.

Machine Features

- Dual Pneumatic Chuck Clamping System:

- The front and rear chucks provide secure and stable clamping.

- The rear chuck includes an air-blowing device to eliminate debris during cutting.

- Adjustable clamping pressure accommodates different load-bearing requirements, preventing deformation of thin tubes while ensuring firm grip of thicker pipes.

- Automated Loading & Unloading System:

- Seamlessly integrates with the cutting process to reduce labor costs and operator workload.

- Enhances operational efficiency and ensures continuous processing.

- User-Friendly Control with Wireless Remote:

- Supports cutting, drilling, positioning, calibration, and emergency stop.

- The wireless handle offers flexible control over clamping pressure and machine functions, making automated production highly practical and intuitive.

After-Sales Service

- Three-Year Warranty

Comprehensive technical support ensures peace of mind and long-term reliability. - Extended Online Support

Technical support is available Monday to Sunday, from 9 AM to 10 PM, covering all time zones. Experienced engineers provide lifetime online assistance, eliminating concerns about time differences. - Local Service Available

On-site support can be arranged where needed, ensuring fast response and effective problem resolution.

Packaging & Delivery

We follow international packaging standards to ensure safe delivery:

- Full protective film wrapping for the entire machine.

- Anti-collision edge protection to prevent damage during transit.

- Non-fumigation plywood cases and iron-reinforced pallets for secure transportation.

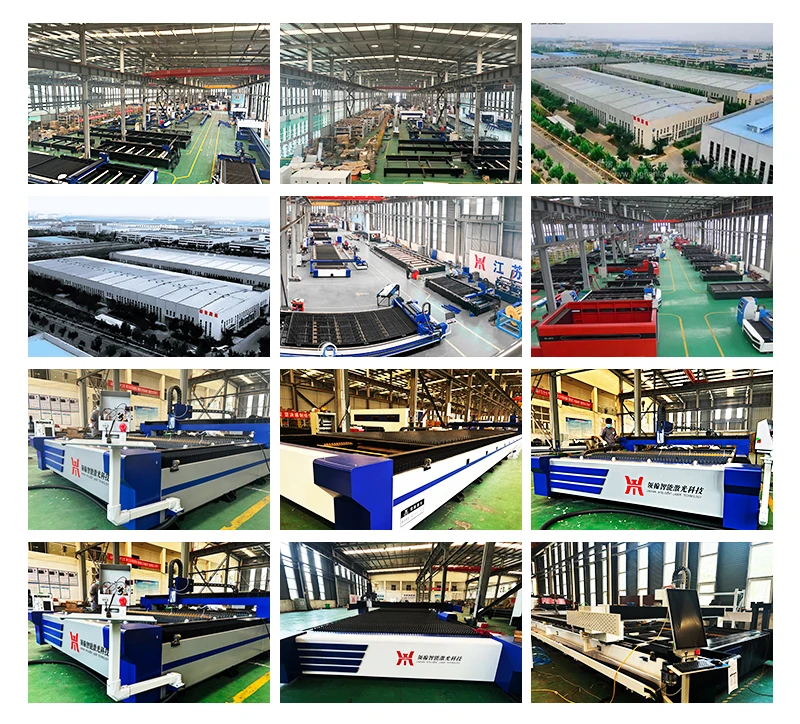

Factory Overview

Our company is a high-tech enterprise specializing in the R&D, manufacturing, and sales of intelligent laser systems. We are committed to delivering global customers cutting-edge laser solutions for applications in precision instruments, sheet metal fabrication, automotive parts, and kitchen & bathroom hardware.

Located in Jiangsu, China, our factory covers over 20,000 square meters, equipped with standardized smart manufacturing facilities. We implement efficient and regulated personnel and production management systems, ensuring organized and high-quality production. Adhering to the philosophy of “Technological Innovation, Lean Production, Research Excellence, and Integrity-Driven Business”, we continuously seek talented individuals to join us in our mission to lead the intelligent laser equipment industry.

Frequently Asked Questions

Q: Can we send you our tube or sheet samples to test the machine’s cutting performance?

A: Absolutely. We welcome customers to send their materials for testing. Please send at least three pieces per size for accurate evaluation.

Q: How do we install and operate the machine?

A: The machine is fully installed and tested before shipment. For minor assembly required on-site, we provide comprehensive training videos and user manuals. Over 95% of our customers are able to get started without on-site installation services.

Q: What should we do if the machine encounters a problem?

A: Please contact us immediately instead of attempting self-repair. Our technical team will respond within 24 hours to provide a professional solution.

Let me know if you need a polished version formatted for a website, product brochure, or marketplace listing (like Alibaba or Made-in-China).

Reviews

There are no reviews yet.